Many joints consist of more than one fastener and tightening together surfaces that are not completely flat can be a very challenging torque problem. The sequence of tightening fasteners can have a major influence on the resulting preload and clamping force, which is what holds two parts together. With such joints, consideration should be given to specifying the sequence in which the fasteners are to be tightened. Because the joint surfaces compress, tightening one fastener in the vicinity of another will affect the preload generated by the first fastener tightened. This is called Cross Talk.

A good tightening sequence ensures that an even preload distribution is achieved in the joint. Since joints containing conventional gaskets have a comparatively low compressive stiffness, bolt preloads in such joints are particularly sensitive to the tightening sequence. Based on experience, if the bolts are in a circular pattern, a cris-cross (star) tightening pattern would normally be specified. For non-circular bolt patterns, a spiral pattern starting at the middle would normally be specified. On critical joints or joints that exhibit relaxation, a tightening pattern that tightens the fasteners more than once can be specified to ensure an even preload distribution.

Sequence based fastening is critical to ensure proper process control and a quality fastening result occurs for many tightening applications. If an assembly exhibits cross talk, a phenomenon where torque to one fastener changes the result to another in the in fastening pattern, altering the sequence is often necessary to achieve proper results. Position Control torque arms are designed to reduce the risk of improperly fastened screws, ensuring that every screw is in the correctly tightened in the correct sequence. An encoded torque arm is perfect because it guides the operators sequence and provides feedback if done incorrectly.

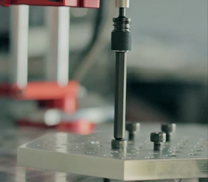

The EZ-Glider position control torque arms by Mountz Inc. help manufacturers detect and eliminate costly screw-fastening errors during the assembly process. Using the EZ-Glider position control torque arm is like putting the eyes and ears of a quality control manager where they are needed most – right on the assembly area. Assembly sequences are easily programmed for the EZ-Glider position control torque arms from an easy-to-use control box. Up to nine sequence programs can be stored and are manually or automatically selected for easy recall. (See the arm in action, view the video).

The position control system consists of a torque arm equipped with an encoder and a control box. The control box is used for programming and it tracks the axis movement by converting angle counts to the precise position of the screwdriver. The location is calculated from encoder values, allowing the operator to easily teach the torque arm a programmed sequence pattern and then use it to control the assembly process. Programming is as simple as moving the driver over the sequence location and then pressing a button. Popular features are driver “lock out”, which disallows activation of the driver if the wrong sequence is attempted and torque adjust, which automatically changes the driver torque to a new torque value if required.

Mountz offers the position control torque arms in various configurations, like a table mounted arm system or a telescoping arm that is mounted above the assembly area. These torque arms are compatible with most air tools, electric screwdrivers and DC control systems. The torque arm can also interface with most intelligent driver systems that store multiple torque programs with external digital I/O control. The Mountz position control torque arm provides a smooth, flexible range of motion as the arm absorbs torque reactions from clutch, stall and other electric & pneumatic screwdrivers.

The Mountz torque arms are designed to improve production and quality control during the assembly process. The ergonomic design of the EZ-Glider torque arm reduces RMI (repetitive motion injury) and CTS (carpal tunnel syndrome). The effortless handling of the torque arm provides comfortable tool operation and increased production. The torque arm eliminates torque reaction and increases safety for your employees.

Using an ergonomic torque arm makes a safer world through accuracy and precision. Position control torque arms ensure fasteners are tightened in the proper sequence. Improve your assembly process. Need assistance with selecting the proper ergonomic torque arm solution? We are happy to help, contact us. You can also request an appointment for a Mountz representative to visit your facility and provide a product demonstration.