When using a power tool, torque control is only one element engineers must resolve and get dialed in for a fastening application. There are other issues that engineers should pay attention to as well. Is there any potential ergonomic issues that may arise from the application? What about cross threading and side load occurring as the assembly operator uses the power tool to run down the fasteners?

It’s not always easy for an operator to use a power tool and start the rundown process for tightening a fastener and keep it aligned properly. Especially when the operator is holding the power tool openly and freely with his or her hand. Cross threading can easily start as soon as the operator uses the power tool. A little tilt to the left or the right and cross threading can start. The sound of grinding occurs and the faster doesn’t run all the way down. Very damaging to the part, especially plastic applications. Now the operator must back the fastener out. Performing hundreds and hundreds of fastening repetitive rundowns, an operator’s aim can easily start missing the mark, which can increase the number of cross threaded occurrences. The time and cost to replace damaged parts slows down the assembly process and creates unnecessary rework.

Providing ergonomic safety for your operators during the assembly process is another element engineers need to determine. The cost for workers’ compensation claims continue to increase. For assembly applications, do you have a strategy for reducing injury loses?

Key Ergonomic Questions to Ask Yourself

– How often do your assemblers complain of fatigue or arm pains?

– How much does a typical injury cost the organization?

– How many workman comp claims have you had?

– How often does a health and safety inspector review your applications?

– What ergonomic solutions are being considered for that application?

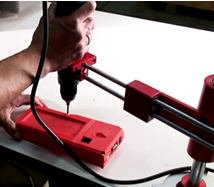

The EZ-Glider linear torque arms by Mountz are designed to improve production and quality control during the assembly process. The ergonomic torque arm prevents side load and cross threading, by securely clasping the electric screwdriver or pneumatic screwdriver and keeping the tool in a perpendicular alignment. The EZ-Glider helps remove the operators influence in the assembly process and strengthens quality control. The ergonomic design of the EZ-Glider torque arms reduces RMI (repetitive motion injury) and CTS (carpal tunnel syndrome). The effortless handling of the torque arm provides comfortable tool operation and increased production.

An ergonomic mindset helps ensure safer conditions. Besides the proper selection of ergonomically correct tools and workstations, manufactures should adopt enterprise wide programs that increase the awareness of ergonomics within administrative offices as well as on the production floor.

A successful ergonomic system incorporates employee participation, which includes discussions across all levels and directions of an organization. It’s recommended to avoid the one-size-fits-all approach. Every ergonomic concern requires its own evaluation, ideally performed by a person competent in such issues. When indicated, control measures should be designed to eliminate ergonomic stresses specific to the results of the evaluation. Finally, effective follow-up mechanisms must be provided.

Mountz offers a variety of torque arm options to meet the various assembly applications and requirements. Using an ergonomic torque arm makes a safer world through accuracy and precision.

Need assistance with selecting the proper ergonomic torque arm solution? We are happy to help, contact us. You can also request an appointment for a Mountz representative to visit your facility and provide a product demonstration.