#214 – Maximum and Minimum Sprinkler Distance Rules, Part 1: Standard Spray Fire Sprinklers

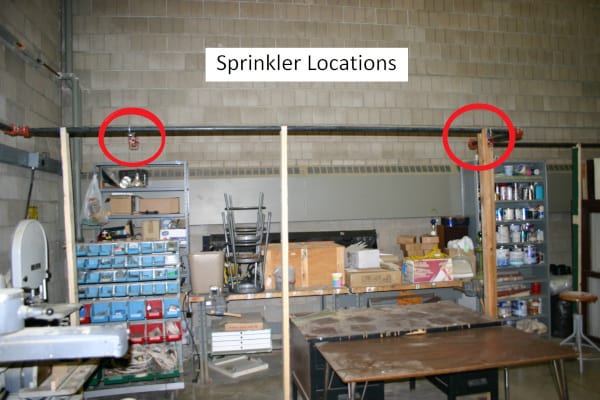

Minimum and maximum distances between the most common sprinkler heads—and from heads to walls—receive careful attention in NFPA 13

A single fire sprinkler can cover an impressively large area, with modern fire codes allowing a single head to protect more than 200 square feet in some environments. But there’s more to sprinkler placement than square footage. Placing sprinklers too close to walls, to each other, or to obstacles can make a fire much more likely to spread. In part one of our series on maximum and minimum sprinkler distance, we take a close look at rules for standard spray sprinklers—such as:

- Why do we need rules regarding distances between fire sprinklers?

- What main factors determine sprinklers’ required distances?

- Pendent and upright fire sprinklers: what’s the maximum allowable distance between two heads?

- Sidewall fire sprinklers: what’s the maximum allowable distance between two heads?

- All sprinkler types: what’s the minimum allowable distance between two heads?

- All sprinkler types: what’s the minimum or maximum allowable distance from walls?

QRFS also invites you to browse our selection of commercial fire sprinklers, including standard spray models, from leading fire-safety manufacturers.

Concerns over late or failed activation create a need for fixed distances from sprinkler heads to walls (and each other)

The installer’s bible for commercial sprinklers is NFPA 13: Standard for the Installation of Sprinkler Systems. NFPA 13’s rules on distances ensure, first and foremost, that sprinklers spray when and where they’re supposed to spray.

In this article, we focus on rules for standard spray sprinklers—a widely-used sprinkler type that serves as the standard for sprinkler performance. The NFPA 13 Handbook explains that they are “proven to be effective for a broad range of hazards and applications by adjusting the water discharge density.”

Decades ago, when standard spray sprinklers were far and away the most common type, these rules might be all that a contractor needed to know. But the experts behind NFPA 13 have added new rules to accompany newer sprinkler types, charging today’s installers with keeping track of minimum distance and obstruction requirements for a variety of sprinklers.

Why do installers need these rules? In short, heat activates fire sprinklers. Consequently, each head belongs in a location that exposes its heat-sensitive parts to the layer of hot gases that build up when fires burn. As we’ve explained in our article on sidewall sprinklers, where walls meet walls—or walls meet ceilings—cooler pockets of air can remain locked in place, delaying activation. And because heat rises, a similar concern exists for sprinklers placed too far below the ceiling.

One other concern remains key to sprinkler distances: cold soldering. If one sprinkler discharges on another, the second sprinkler will cool. As a result, that sprinkler may not discharge on time—or at all. Proper spacing can prevent this unwanted problem from taking place.

Sprinkler distances vary with system types and sprinkler design

The maximum and minimum sprinkler distance between standard spray sprinklers—and from heads to walls—vary with two main factors:

- Sprinkler characteristics. The design and performance of fire sprinkler heads have a significant impact on distance and obstruction requirements. Chapters 10 through 15 of NFPA 13 (2019) provide these guidelines in detail.

- Sprinkler orientation. NFPA 13 has rules specific to pendent, upright, and sidewall heads in subsections throughout the chapters above.

Spacing requirements between sprinkler heads can also vary with the type of construction—that is, with the presence of combustible materials or fixed obstructions. In NFPA 13, the type of sprinkler system installed also plays a role in determining the maximum space between fire sprinklers. Sprinkler systems can be broken into two types:

- Systems designed with the pipe schedule method. Designers use the building’s hazards, water supply, and sprinkler placement density to determine appropriate pipe size for sprinklers on branch lines.

- Hydraulically designed sprinkler systems. Designers rely on mathematical analysis of pipes’ capacity to distribute water to fire sprinkler heads.

The sprinkler’s maximum distance from walls correlates with these spacing requirements. As the maximum spacing between sprinklers increases, so does the maximum allowable distance from walls.

NFPA 13 modifies these requirements for small rooms, curved surfaces, and angled walls. Further, installers may sometimes place specially equipped or specially designed sprinklers close together. One such exception is the in-rack sprinkler, used when ceiling-mounted sprinklers can’t effectively protect items stored on racks. NFPA 13 also allows close spacing for heads equipped with baffles—bowl or disc-shaped accessories that keep one sprinkler’s spray from prematurely cooling another head.

Maximum spaces between standard upright and pendent sprinklers vary with a room’s hazards

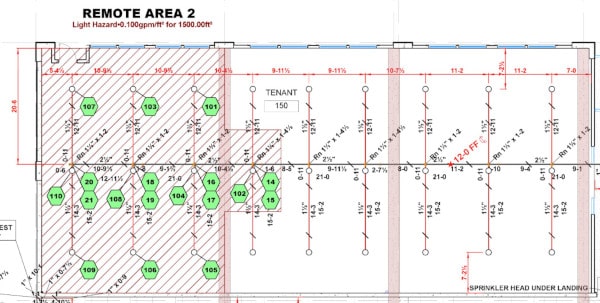

For standard upright and pendent sprinklers, NFPA 13 establishes a maximum sprinkler-to-sprinkler distance using five tables. Tables 10.2.4.2.1(a) through 10.2.4.2.1(d) set spacing and protection area requirements for four hazard types:

- Light Hazard (10-15 ft). Excluding heads in combustible concealed spaces, all sprinklers in this category have 15 feet (4.6 meters) of maximum allowable spacing between them.

- Ordinary Hazard (15 ft). All sprinklers in these environments have a 15-foot (4.6-meter) maximum.

- Extra Hazard (12-15 ft). The rules vary by system type. Pipe-schedule systems and hydraulically calculated systems with a density at or over 0.25 gallons per minute per square foot have a 12-foot (3.7 meters) maximum distance between sprinklers. Hydraulically calculated systems with less density have the standard 15-foot (4.6-meter) maximum.

- High-Piled Storage (12-15 ft). Hydraulically calculated systems with a density at or over 0.25 gallons per minute per square foot have a 12-foot (3.7 meters) maximum. Hydraulically calculated systems with densities under 0.25 have the standard 15-foot (4.6-meter) maximum.

Two exceptions deserve a mention:

- Sprinklers in some light-hazard, combustible concealed spaces (see 10.2.6.1.4) have especially detailed requirements. Maximum spacing varies from 10 to 15 feet.

- Where extra-hazard occupancies and high-piled storage feature bays made from solid structural members, spacing may increase to 12.5 feet. However, this doesn’t apply to calculated systems with densities under 0.25 gallons per minute per square foot.

Hazards and concerns over cold soldering determine the maximum spacing between standard spray sidewall sprinkler heads

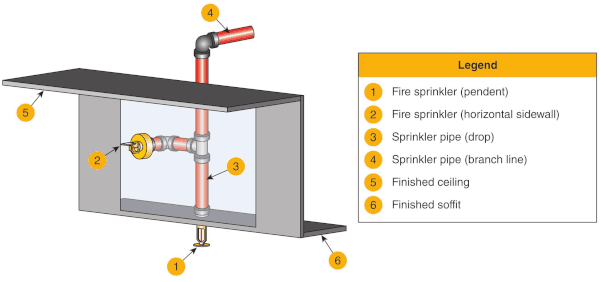

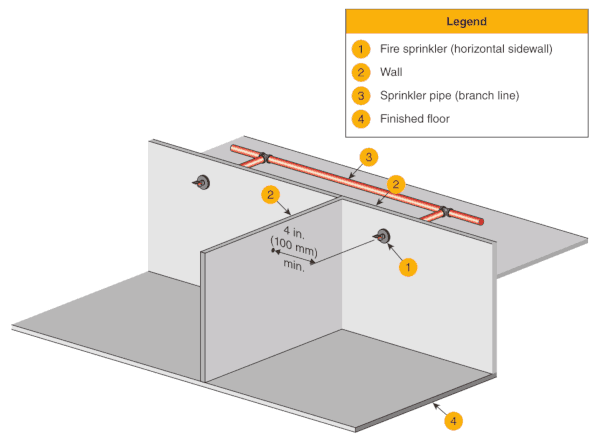

Sidewall sprinkler heads typically mount on a wall. When it’d be hard to use pipes in the ceiling, or when overhead sprinklers simply wouldn’t look good, sidewall sprinklers provide designers an alternative. While the distance between sprinklers is a fairly simple topic for pendent and upright types, NFPA 13 has detailed rules for standard sidewall fire sprinkler heads.

First off: installers can’t measure these distances from the inside edges. Nor can they always measure for the shortest possible length.

From the 2019 edition of NFPA 13

10.3.4.1.1 The maximum distance permitted between sidewall spray sprinklers shall be based on the centerline distance between sprinklers on the branch line.

10.3.4.1.2 The maximum distance between sidewall spray sprinklers or to a wall shall be measured along the slope of the ceiling.

In section 10.3.4, NFPA 13 clarifies that the maximum distance also varies with the hazards involved:

- Light-hazard areas allow a maximum distance of 14 feet (4.3 meters).

- Ordinary-hazard areas permit a distance of only 10 feet (3 meters).

- Sidewall heads protecting spaces below overhead doors have maximum distances for light-hazard areas, even when installed in ordinary-hazard environments.

To stop cold soldering, sidewall sprinklers placed on opposing or adjacent walls must not be within the maximum protection area of another sprinkler. Additionally, installers can’t place these sprinklers back-to-back without a lintel (a beam typically placed over a door or window) or soffit (a lowered section of a ceiling) between them. This can stop a sprinkler from spraying needlessly—or prevent cold soldering of one sidewall head by another. However, that lintel or soffit can’t exceed 16 inches in width unless it’s protected by a pendent head.

Minimum distance: With few exceptions, NFPA 13 requires at least six feet between all standard spray fire sprinklers

While maximum distances between sprinklers vary with the room’s hazards and fire sprinkler types, the minimum sprinkler distance from head to sprinkler head changes with only two factors:

- Are sprinklers (properly) equipped with baffles?

- Are they in-rack sprinkler heads?

NFPA 13’s rules for sidewall heads closely resemble those for pendent and upright types. Those guidelines, found in sections 10.2.5.4 (pendent and upright) and 10.3.4.4 (sidewall), require 6 feet of clearance between heads. That minimum distance is measured from the center of each sprinkler head (or, “on center”).

Baffles allow for reduced spacing between heads when they:

- Protect the actuating elements (heat-sensitive bulbs and links)

- Consist of “solid and rigid material that will stay in place before and during sprinkler operation”

- Are no longer than 8 inches and no higher than 6 inches

- Have tops that extend from 2 to 3 inches above upright and sidewall deflectors

- Have bottoms that “extend downward to a level at least even with” pendent and sidewall deflectors

NFPA 13 makes one final exception for in-rack sprinklers. Because they’re designed to work even when closely spaced, in-rack sprinklers may be placed closer than six feet together (10.2.5.4.3).

All standard spray sprinklers have four-inch minimum spacing from walls and maximums that vary with room shape and size

All standard sprinkler heads—pendent, upright, and sidewall—have the same minimum sprinkler distance from walls: four inches. For sidewall heads, that’s the distance from an end wall (10.3.4.3.1). Pendent and upright sprinkler heads keep this minimum distance from all walls (10.2.5.3). In doing so, these heads stay away from sources of cool air that might delay their activation or surfaces that could block the intended spray pattern.

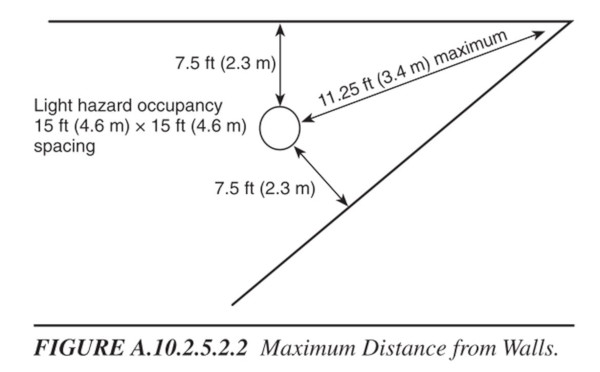

However, NFPA 13 has much more to say about the maximum distances between fire sprinklers and walls. For all head types, the maximum distance between heads and walls is half of the maximum distance permitted between two sprinkler heads (the latter detailed in the sections above). For example, an upright sprinkler in an ordinary hazard environment can be as far as 15 feet from an adjacent head. That same head can be up to half that distance—as far as 7.5 feet—from a wall.

For pendent and upright heads, NFPA 13 has more detailed requirements on distances from walls, including:

Exceptions for irregular or angled walls (10.2.5.2.2).

When two walls meet at a narrow angle, a sprinkler placed just a few feet away from those walls may wind up being a considerable distance away from the corner space it’s supposed to protect. This is just a quirk of design, and NFPA 13 makes allowances for these odd-shaped rooms. It prescribes a longer maximum distance between the head and the corner where walls meet at odd angles.

Thus, whereas the distance from heads to the wall normally may be no further than 0.5 times the maximum allowable distance from sprinkler head to sprinkler head (0.5 x the maximum distance of 15’ between sprinklers = 7.5’), if there is a sharp angle in a deep corner, this maximum to the corner jumps to 0.75 (.75 x 15’ = 11.5’), as shown in the image below:

Exceptions for small rooms (10.2.5.2.3).

Light-hazard compartments under 800 square feet may follow different rules. When these small rooms have unobstructed construction, sprinklers’ maximum distance from walls becomes 9 feet. For more details, see the section referenced above in NFPA 13.

To be continued: NFPA 13’s rules on sprinkler head distance

This concludes part one of our look at NFPA 13’s rules regarding maximum and minimum sprinkler distances from walls and between heads. We’ve only scratched the surface of the standard’s extensive guidelines for safe and effective sprinkler placement—so stay tuned for more.

If you’re looking for versatile standard spray sprinkler heads, take a look at QRFS’s selection of UL-listed and FM-approved heads. Our stock of Tyco, Senju, Victaulic, and Viking heads features a wide range of finishes, response types, and temperatures for a broad spectrum of buildings and applications.

View our full inventory of commercial fire sprinklers.

Questions? Call us at +1 (888) 361-6662 or email support@qrfs.com.

This blog was originally posted at blog.qrfs.com. Visit us at Facebook.com/QuickResponseFireSupply or on Twitter @QuickResponseFS.