Imported cavity pumps play an important role in many industrial applications with their unique working principle and excellent performance. To ensure that this pump can operate continuously and stably, the design and manufacture of its various progressing cavity pump parts are crucial.

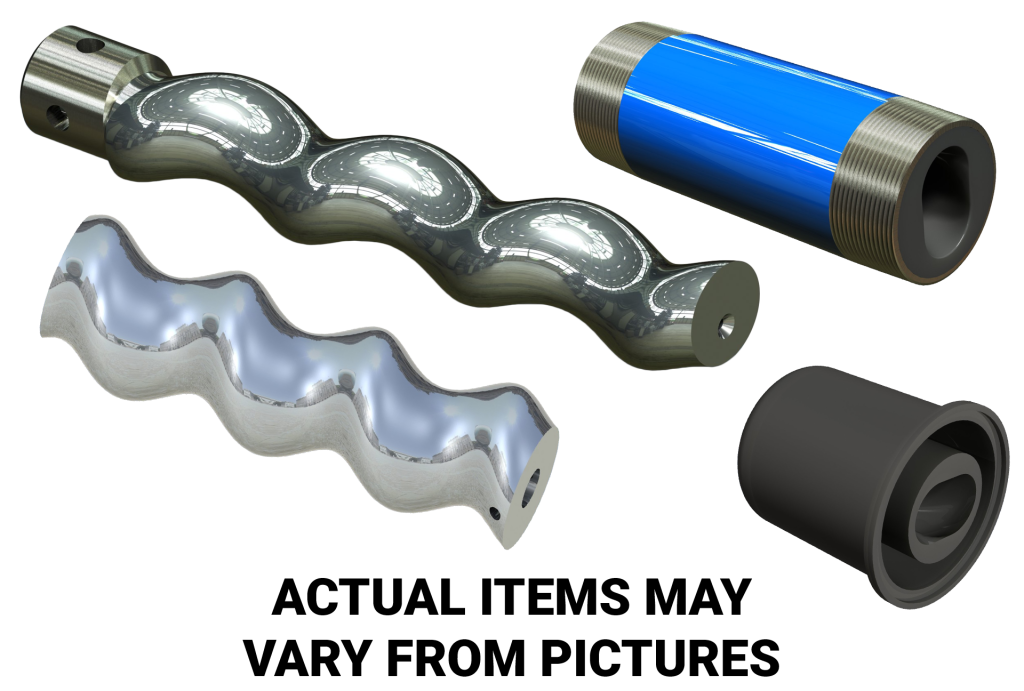

The core components of imported cavity pumps include rotors and stators. The rotor has a spiral structure, forming a series of closed cavities between it and the inner wall of the flexible stator. When the rotor rotates, these cavities will move continuously along the axial direction to achieve fluid transportation. The precise coordination of the rotor and stator not only ensures the self-priming function of the pump, but also enables it to transport viscous and particulate fluids.

In addition, other progressive cavity pump parts of imported cavity pumps include bearings, seals and pump bodies. The choice of bearings directly affects the smooth operation and service life of the pump. Suitable seals can effectively prevent leakage and ensure that the fluid circulates inside the pump. The material and structural design of the pump body determine its corrosion resistance and wear resistance under different working conditions.

With the continuous improvement of the performance requirements of fluid conveying equipment in industrial production, the design and manufacture of progressive cavity pump parts have also become more specialized and refined. Some leading pump manufacturers are constantly optimizing the material selection and processing technology of key components to improve the reliability and service life of the overall product.

Take Tianyue Company as an example. As a world-renowned imported cavity pump manufacturer, the company has accumulated rich technical experience in the fields of materials science and mechanical engineering. They use high-performance engineering plastics to produce stators and perform special wear-resistant treatment on the rotor surface, which greatly improves the service life of the pump. At the same time, Tianyue also provides a variety of gear, bearing and seal combinations for different application scenarios to ensure that the pump can continue to operate stably under various working conditions.

In addition, some manufacturers of progressive cavity pump parts are also constantly promoting technological innovation. For example, some advanced sealing solutions use adaptive sealing forms to effectively respond to changes in fluid pressure and temperature, thereby minimizing leakage and energy loss. These innovations help promote the progress of the entire imported cavity pump industry.

In general, the design and manufacture of progressive cavity pump parts is a complex project that requires manufacturers to master a wealth of knowledge in materials science, mechanical design and process control. Only by continuously improving the performance and reliability of key components can the overall pump products be more efficient and durable. This will also be the key to promoting the widespread application of imported cavity pumps.